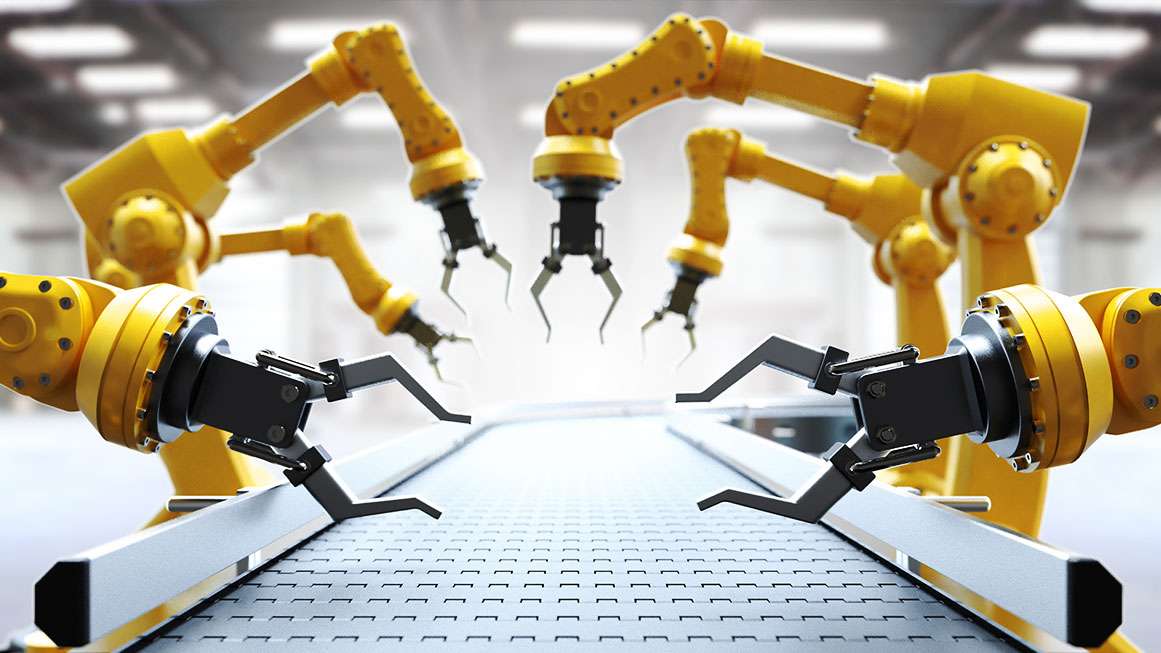

There are currently around 120,000 global warehouses. An additional 50,000 are expected to be added by 2025. Over the next few years, more robots will be deployed into these warehouses—the logistics market—than in all other application categories combined, including farming, medicine, and home use. The 2020s will see the beginning of robotification in services, just as the 1960s witnessed the automation of industries and a boom in productivity.

Box Bots

General Motors (G.M.), in 1961, introduced industrial robots. The New Jersey plant had a basic robotic arm installed. The machine had been invented by Unimation, a company founded by the father of robotics, Joseph Engelberger—a self-professed Isaac Asimov enthusiast. G.M. had been established in 1969. G.M. had rebuilt the Lordstown factory, Ohio with an array Unimates for performing welds. The facility quickly achieved a double jump over the previous production rate and was the most productive factory worldwide. This factory will be sold to Lordstown Motors (which plans to create electric trucks) in 2020. Automotive manufacturers around the world were some of the first to use industrial robots.

An annual robot census is published by the International Federation of Robotics. It was established in 1987. It found that nearly 400 million robots were working in industrial plants around the globe when 2020 started. This is twice what it had five years prior. For the first time in history, more than half of global robot sales were for services and not industrial purposes. Even though the former is likely to grow, it’s expected that service robot installations will rise by over 200 percent within a short time.

An estimated half of all service-robots can be found in logistics, and about one-fifth are used for inspection. Robotic technology is only one-fifth of the total market. The military was an early supporter and continues to be a strong advocate for robotic technology. Rest of the market includes everything, from fruit picking and professional cleaning to delivery in hospitals.

G.M. robotification was the service-bot equivalent.Amazon purchased Kiva Systems in 2012 for $775million. Kiva developed a self-propelled, turtle-like robot capable of moving around warehouses with entire packages.

Walmart and Amazon require more than just information between sellers and buyers in cyberspace. Walmart and Amazon also need to have physical warehouse exchanges. This is how seamless shopping can be achieved with “one click”. The cloud’s “one-click” shopping experience is made possible by Kiva-class service robots. They are wirelessly and directly controlled in real time by the cloud.

The annual net increase in warehouse area has increased by 400 percent over the last decade. This helps to explain the almost identical 400% rise in the number of service robots sold into warehouse and logistic supply chains over the five-year period.

E-commerce is more than just increasing the need for warehouses. It has also changed how they function. E-commerce has changed the function of warehouses. Before, products arriving in warehouses would be redistributed to nearby retailers on pallets. There, staff would sort and unpack the merchandise onto shelves. E-commerce is allowing the second half of the distribution process to be pushed upstream. Warehouses are multistory structures larger than football pitches. Single packages such as toothpaste tubes and books can now be grabbed, packed, and shipped directly to consumers’ doorsteps.

E-commerce is pushing smaller warehouses towards the edge of supply chains, making it more convenient for consumers. Service bots address another issue. Because these edge facilities must be located in areas where more real estate is available, service bots help operators maximize the use of a building’s space by packing items in tighter. Robots and automated systems are safer in these high-density spaces. The pinnacle of density, a kind of Rubik’s Cube–like design for bins and packages, leaves no room for people.

This robot will be able to operate in both hyper-dense warehouses and remote warehouses. While humans will remain involved in the production and front-end, the storage, moving and sorting packages will all be done autonomously. This is similar to how a warehouse-scale computer stores, moves and sorts data.

Robots that handle packages are part of the wider warehouse automation trend. They can be used inside buildings as well as for last-mile deliveries. The service industry will see robotification in every sector. From security and safety to environmental monitoring and assessments to education and farming to general-purpose cleaning to health care, all aspects of services are being automated. Robotification will improve performance and adaptability as well. The fastest growing market for service bot deployments is medicine and agriculture.

John the Farmer

John Froelich was the inventor of the farm tractor. A few years later, he founded the Waterloo Gasoline Traction Energy Company. The name is to distinguish the company from steam-driven, inferior machines. He sold his company to John Deere, a manufacturer of plows in 1918.

John Deere’s Precision Farming Group, almost 80 years later, began to work on a GPS guided tractor. That came to fruition in 2002, when the company debuted a GPS-guided self-navigating farm vehicle—the machine that marks the dawn of agricultural cyber-physical systems. Although self-driving vehicles may not be possible in the near future, at least two thirds of North American crops are already using self-guided cyberphysical machines. This figure stands at 90 percent in Australia.

Overall, agriculture accounts for a relatively small piece of the robot market—about $5 billion a year. However, this is changing. A.I. is the key to cloud computing. This improvement is comparable to that of the gasoline engine over steam. We’ll soon be able to see tractors that are not as large and expensive. Swarm farming robotsThese machines are smaller in size and less expensive than the larger industrial-scale models, which can be used for precise fertilization and weeding. A combination of A.I. enabled vision systems to see if the fruit has ripened and soft materials that can be grabbed by grabbers will lead eventually to fruit-picking robotics. It’s just the right time. Demographic trends indicate a growing labor pool in agriculture as well as a rising global demand.

Dr. Bot, M.D.

Although medical robots still have a long way to go, they are already worth $5 billion. Intuitive Surgical’s da Vinci robot was approved by the Food and Drug Administration in order to be used during endoscopic surgeries two decades ago. The FDA approved Mazor Robotics’ spine surgery robot and gave Auris the green light in 2018 for robots used in lung and endoscopic procedures.

Many innovations involve an elastic usage of the word Robot. The da Vinci machine could be described more accurately as “teleoperated” (or “robot assisted”): It is controlled remotely by a person, while the machine provides precision. The machine does not operate autonomously. The same is true of “exoskeletons,” a class of Iron Man–style devices that help humans lift and move heavy objects, minimizing strain and enhancing strength. Although unwieldy, impractical prototypes were made in the 1960s, we have only recently been able to create useful exoskeletons thanks to lightweight materials, advanced power systems, sensors and A.I.-enabled computer software.

In the construction, medical, and manufacturing markets, exoskeletons have begun to make a comeback. Sarcos Robotics, a partner with Delta Airlines to handle baggage handling, recently tested its new system in field trials. Sarcos asserts that exoskeletons can improve employee productivity up to fourfold when used in heavy-lifting jobs.

Ekso Bionics received FDA clearance in June 2020 for its exoskeleton, which aids patients who have suffered brain injuries to regain their mobility. Honda also began using the technology for wearable exoskeletons to assist the elderly after it retired its Asimo robot, a walking machine. We can expect wheelchairs will disappear as exoskeletons are more affordable, durable, and comfortable. In the 2020s, exoskeletons will be a multibillion dollar industry.

The introduction of service robots will bring increased safety to high-risk workers. Construction, landscaping, agriculture, ranching and fishing are the most hazardous occupations.

Tomorrow’s bots

What new types of machines could be commercially profitable? This is the most intriguing question.

Consumer machines are not included in the annual industrial robot census. In 2020, nearly 20 million robots were on sale in the US. These are—for now—mostly low-cost devices for relatively low-value applications: vacuuming, mowing lawns, toys, etc. These devices are closer to automated washing machines than to the anthropomorphic robots Asimov imagined.

Like the auto and the phone, true robots are possible only when all the technologies have matured. Henry Ford would not have been able to build his vast enterprise without the combination of gasoline engines, petroleum refining and an assembly line. None of these technologies were invented by him or his company. In the same way, iPhone wouldn’t have been possible without the maturity of three technologies which Apple did not invent: silicon microprocessors, small TV screens, and lithium batteries.

Three enabling technologies are now mature for untethered, useful robots: vision “chips”, synthetic “muscles” and lithium batteries. Combine these technologies with the ubiquitous supercomputing speed and you have a revolutionary solution.

Vision chips’ collapsing sizes and growing capabilities were not driven by roboticists, but rather by consumers who want digital cameras embedded into smartphones. This led to automotive engineers seeking chip-sized radars for improved cruise control and other related applications. Roboticists have been searching for a way to imitate muscles. The answer is now in materials science. There are electrical, pneumatic and polymer actuators available that can provide the required efficiency, power and range of motion as well as durability and self-repair. The onboard power that can animate all of it! Exxon developed lithium chemistry in the 1970s.

With the rapid growth rates currently underway, service robots for professional work will be an ever more common feature of daily life for a growing number of people. Until now, the service sector has been infamously immune to the kinds of machine-driven productivity gains seen in factories and farms—gains that invariably create new kinds of work and a widespread growth in wealth.

It was obvious that cars would have superior performance when they were introduced. Even though it wasn’t as useful as a horse-drawn wagon, the original Packard was still able to perform better than any other car. With the Model T’s introduction in 1919, the path to success and the speed of change and growth became apparent. In fact, by the 1930s about 20% of Americans owned cars. There were hundreds of American automakers that sprung up along the way. This created new areas of indirect and direct employment and fortunes.

Home-owners will be able to start purchasing lower-cost robots for home care, such as those that can assist the elderly with their daily tasks. Robot manufacturing is expected to mature in 2020. A new type of machine will be domesticated at that time. Who knows what else will come of it? Steffi Paepcke is a leader of the Toyota Research Institute’s team. She said that if the Toyota Research Institute asked horse riders what they desired, the answer would be “a faster horse.” Sometimes it can be hard to envision a different future from what is currently in place.

Some people have not found the rise and popularity of robotics thrilling. With the decline in automobile production jobs despite a rise in output, President John F. Kennedy established an Office of Automation and Manpower. This was to tackle “the biggest domestic problem of the Sixties”: maintaining full employment while automation is gradually replacing humans. About 60 percent of all the jobs created during that time are gone today.

However, if labor-saving technologies were net job killers, then the unemployment rate would be constantly rising throughout modern history. This has not happened. There are many types of work that can be done as some skills disappear. Robotification promises us many of the same benefits as the industrial mechanization: More business, greater wealth and better well-being.